What We Do

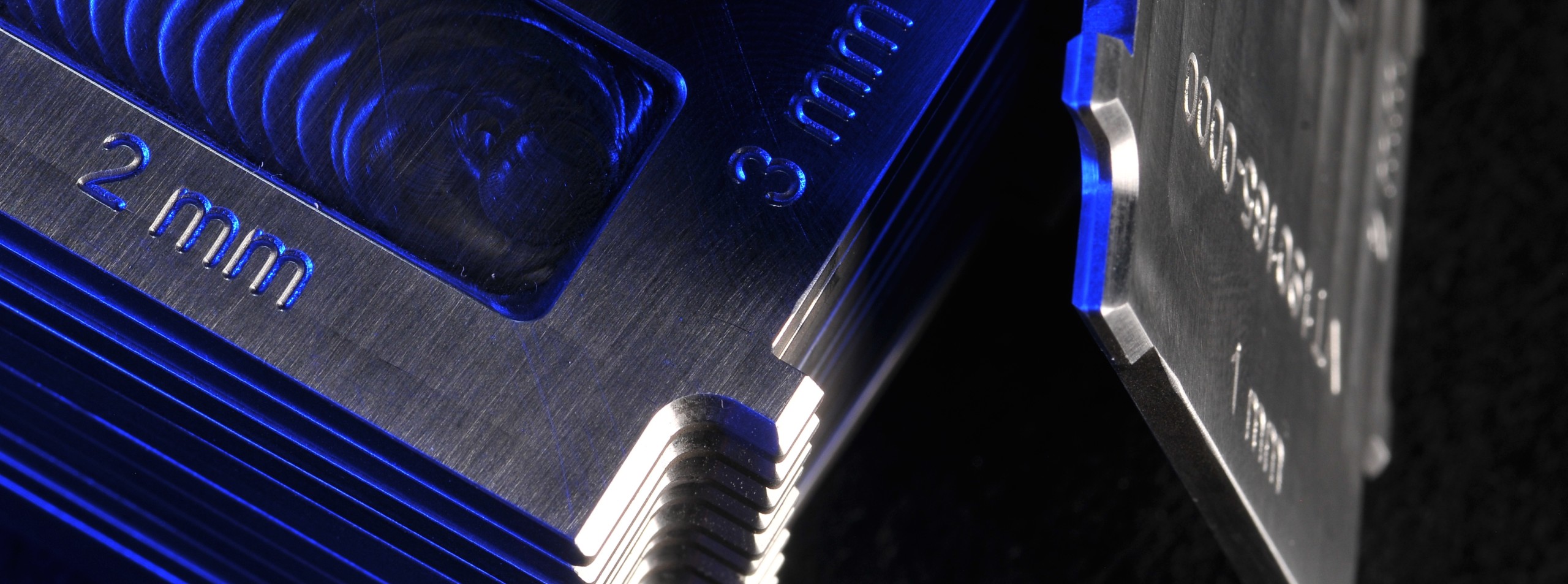

Cutter Innovations

Quality Focused AS9100 Certified Machine Shop

Cutter Innovations is a Colorado-based AS9100 certified machine shop & manufacturing company specializing in the precision machining of exotic metals and product development. At our state-of-the-art precision CNC machine shop, our talented staff has over 50 combined years of experience and is capable of delivering tight tolerances in exotic materials, on time, and to your specifications.

Our engineers have industry-recognized expertise in solid modeling (Certified SolidWorks Professionals) and specialize in assisting our Customers with product development. We’re able to offer our Clients the following capabilities:

AS9100 Certified Machine Shop

Prototyping

Manufacturing

Engineering

Inspection

Management

Quality Assurance

5 Axis Machining

3, 4, and 5 axis machining centers to meet both prototype and production requirements.

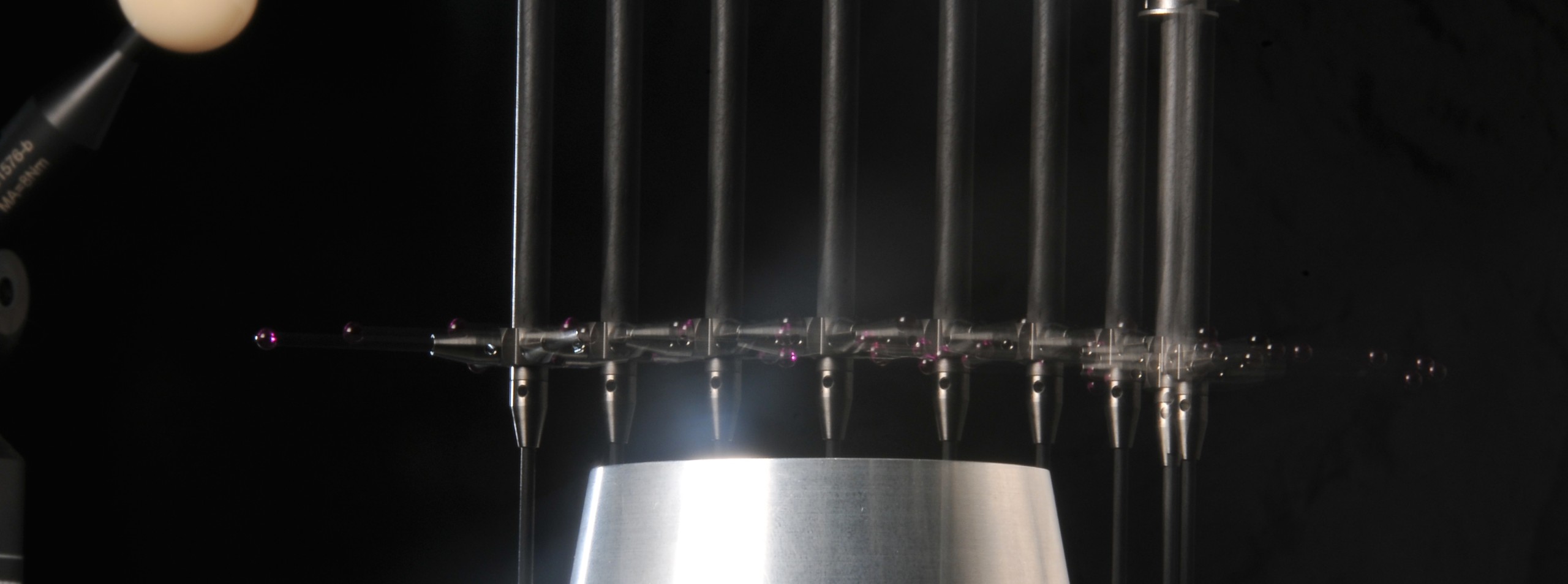

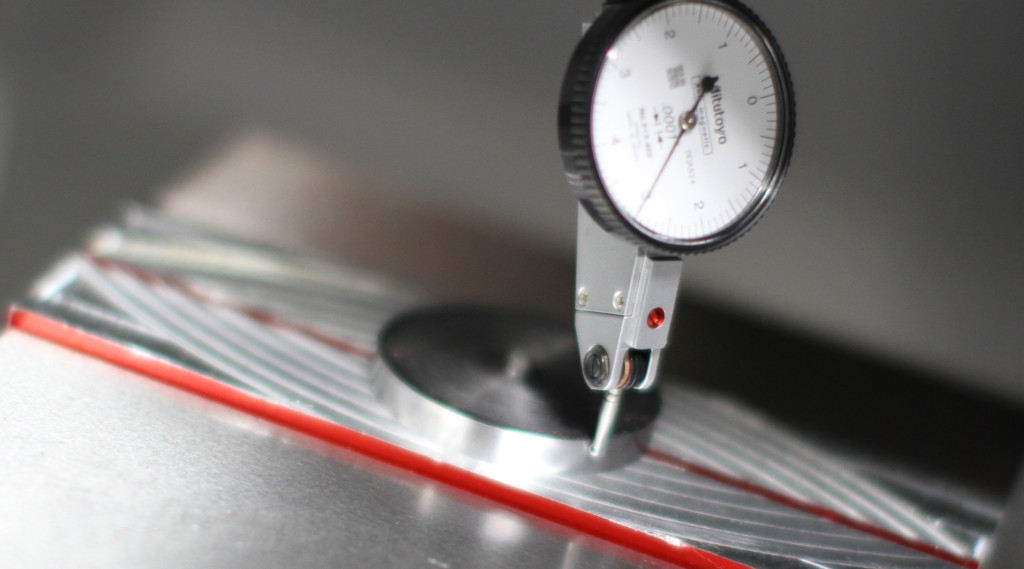

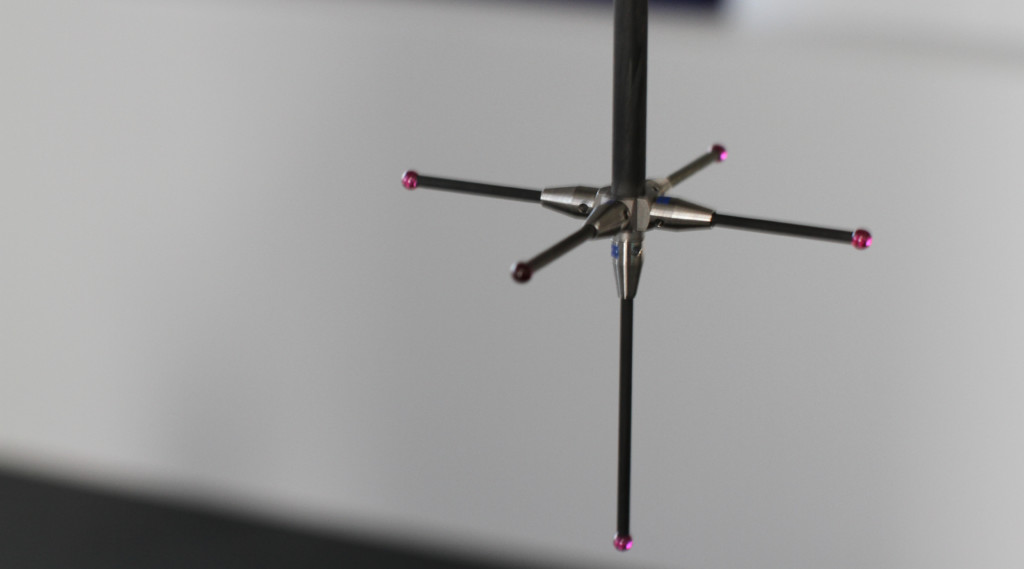

Inspection

State of the art Zeiss scanning CMMs ensure automated, precise measurements. Cutter strives to ensure 100% parts quality on each order that passes through our facility by incorporating robust, CNC inspection plans using best-practices. Digital part inspection reports are available at no cost to our Customers.

Inspection

State of the art Zeiss scanning CMMs ensure automated, precise measurements. Cutter strives to ensure 100% parts quality on each order that passes through our facility by incorporating robust, CNC inspection plans using best-practices. Digital part inspection reports are available at no cost to our Customers.

Quality Assurance

Our AS9100 quality system was developed with our core competencies of low-volume 5-axis machining in mind. In order to meet the Standard and not lose any time in delivering quality work, Cutter Innovations developed a custom AS9100 quality system that relies heavily on employee training.

Engineering

Cutter Innovations strongly believes in quality work and maintaining strong working relationships with our Clients. With us, you can expect nothing short of our best possible effort and we’re always willing to offer insight and recommendations to help make your products better. Whether its high-speed precision machining, 5 Axis Machining, precision CNC turning in exotic metals, EDM machining, or product development and prototyping, you can trust our team to get quality results. Contact us today and send us your product specifications!

Engineering

Cutter Innovations strongly believes in quality work and maintaining strong working relationships with our Clients. With us, you can expect nothing short of our best possible effort and we’re always willing to offer insight and recommendations to help make your products better. Whether its high-speed precision machining, 5 Axis Machining, precision CNC turning in exotic metals, EDM machining, or product development and prototyping, you can trust our team to get quality results. Contact us today and send us your product specifications!

Know more

About Us

Your Choice for Precision Aerospace Machining

The Challenge

The machining of precision parts presents aerospace machine shops with a number of unique challenges including:

- The size and the shape of the components result in highly complex contours that require 5 axis CNC machining to ensure precision.

- The components must be machined in accordance with quality control guidelines to meet extremely tight tolerances.

- The metals used to create the aerospace engine parts are typically hard and high-temperature resistant which makes them difficult to machine.

- Additional materials such as lightweight aluminum, special alloys, and carbon-fiber composites also need to be worked into the manufacturing process.

The Solution

Cutter Innovations

At Cutter Innovations, we provide a custom-built service designed to precisely meet all of your aerospace parts manufacturing requirements.

- Our quotes are easy to understand and are delivered in a timely manner, with open-book bidding on request.

- We use state-of-the-art 5-axis machines and specialized software in our aerospace machine shop to manufacture parts that meet our Customers’ precise needs.

- Our high-quality vendor network enables us to handle all aspects of component manufacturing.

- Through innovation and engineering excellence, our highly skilled staff enable us to deliver components more economically and more efficiently than other aerospace components manufacturers.

- As you would expect from a company like Cutter Innovations, ALL of our work is totally quality controlled and guaranteed.

Partnering With

Cutter Innovations

Cutter Innovations is a Colorado-based AS9100 certified manufacturing company specializing in precision machining of exotic metals and product development.

At our state-of-the-art precision aerospace machine shop, our talented team has over 50 combined years of experience. We deliver tight tolerances in exotic materials, on time and to your specifications.

With over two decades of research and development experience, we have manufactured precisely engineered components for the aerospace, medical, oil & gas and alternative energy industries.

Based on our wide R&D expertise, we are uniquely positioned to offer our Customers engineering consultancy services. We treat our Customers and their intellectual property with total confidentiality and respect.

Our AS9100 Aerospace

Machining Methods

Cutter Innovations offers innovative engineering design consulting services with core competencies in 5-axis, wire EDM, conventional milling and turning. We use CMM technology in our inspection process to provide the highest quality precision. These competencies give us advantages in responsiveness, serviceability, and quality assurance. We aim to be a vital component to our Customers’ business by ensuring impeccable steps for quality control.