about our

Aerospace Machining Company

Owners, Mike & Ruthie Swartzlander...

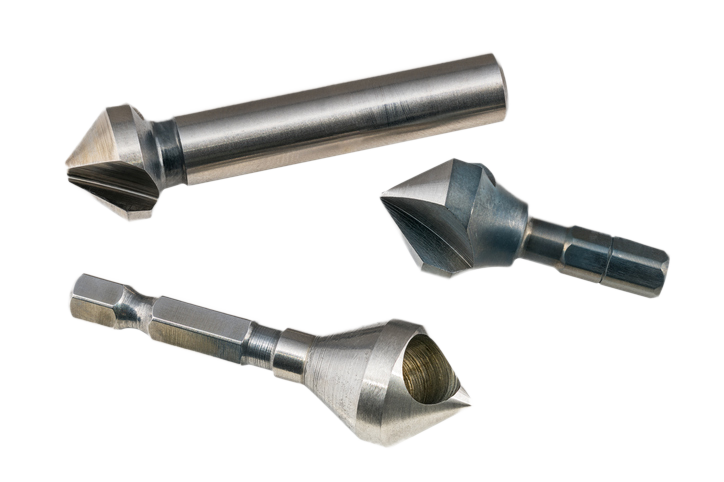

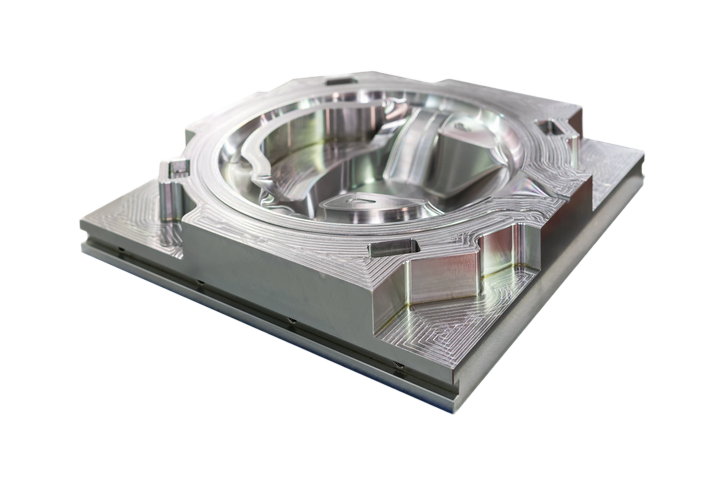

Cutter Innovations is an AS9100 registered company that provides quality-driven machining services that add value to our Customers’ projects. We are a specialized manufacturer in precision machining services with over two decades of research & development and engineering experience. Cutter Innovations has delivered components to the aerospace, medical, oil & gas, and alternative energy industries.

COMPANY

HISTORY

Mike & Ruthie Swartzlander were highschool sweethearts who both graduated as engineers from the Colorado School of Mines. Early in their careers, in both the medical and aerospace industries, they discovered a shared love of manufacturing. Cutter Innovations started in 2011 with a belief that building a small machine shop with world-class capabilities would attract Customers looking for high-end machining without the headaches of high costs and long lead times. That concept has allowed Cutter Innovations to grow while expanding its flexibility, responsiveness, and capabilities!

COMPANY

BELIEFS

Cutter Innovations believes that business is all about relationships. Our Customers, vendors, and employees are all part of the organization with the same goal. Treating others as we would want to be treated is how we strive to grow and nurture our relationships in the long term.

COMPANY

VALUES

Cutter Innovations values Customer intimacy and the opportunity to work with and serve our Customers over and over again while protecting intellectual property. We value hard work and a can-do attitude - we aren’t the types to shy away from a difficult project! Finally, we value integrity in all that we do.

MACHINING

Methods

HOW WE DO IT

Our Process

HOW WE DO IT

Our Process

Consider us your source for the following

Project Requirements:

AS9100 Registered.

An orderly shop with employees that take pride in their facility and its processes.

Open book bidding process and Customer visits are welcome

Product development, including solid modeling, prototyping, and manufacturing services.

Female owned and operated.

We welcome a wide variety of projects, low to mid-volume production capacity.

Customer-oriented, collaborative and consultative approach.

Machining centers and inspection equipment matched to consistently produce tight-tolerances in exotic materials.