Expertise in Aerospace Milling

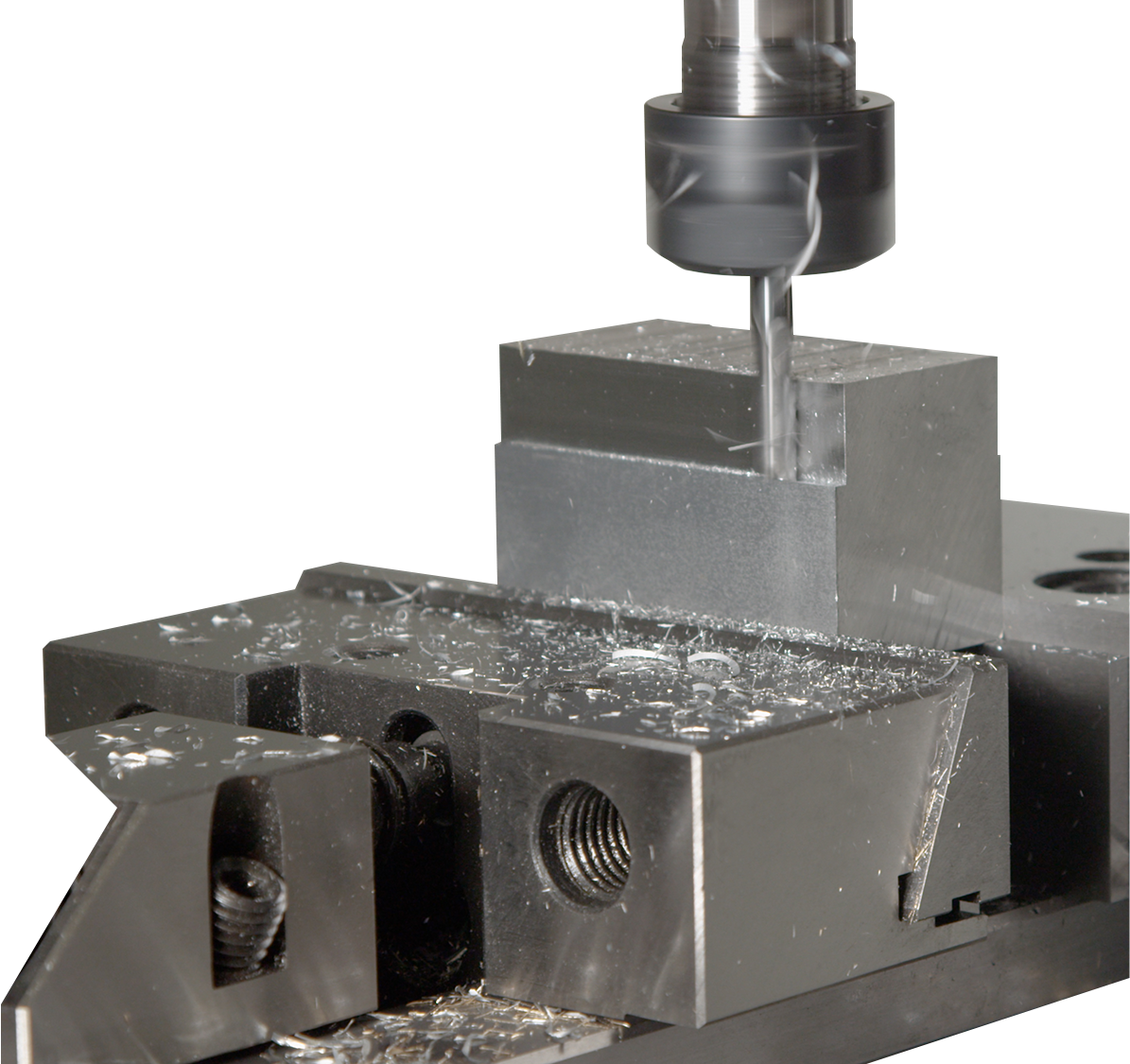

At Cutter Innovations, our focus on aerospace milling ensures that we can meet the strict specifications and rigorous quality standards of the industry. Our advanced CNC milling capabilities allow us to machine parts with exceptional accuracy, ensuring that every component meets the necessary dimensional and performance requirements. Whether it’s aluminum, titanium, Inconel, or other exotic metals, our experienced machinists and engineers have the expertise to handle complex geometries and tight tolerances.

Aerospace components often require intricate features, lightweight structures, and extreme durability. Our precision CNC milling processes allow us to produce these parts efficiently, reducing material waste while maintaining the structural integrity of each component. We work closely with aerospace clients to ensure that every part meets industry regulations, including AS9100 standards, to guarantee quality and reliability.

Conventional Milling & Turning Capabilities

In addition to CNC milling, Cutter Innovations has a successful track record in conventional milling and turning operations. With working envelopes of up to 20” x 40” and turning capacities of ø14” x 20”, we can accommodate a wide range of aerospace components, from small intricate parts to larger structural elements.

Our conventional milling expertise is particularly valuable for mid-volume mixed-part production, where cost-efficiency and precision are equally critical. We optimize tooling and machining processes to reduce production costs without compromising quality. Whether it’s prototypes, small-batch production, or ongoing aerospace manufacturing, we can quickly adapt to project specifications while maintaining the highest precision levels.

Advanced CNC Milling Technology

Our CNC milling capabilities allow us to manufacture complex aerospace components with high efficiency and accuracy. Our facility features multi-axis CNC machines capable of handling reducing the need for multiple setups. This improves consistency and ensures repeatable results across production runs.

Key benefits of our aerospace milling services include:

- Precision machining for high-performance aerospace components

- Multi-axis CNC milling for complex geometries and tight tolerances

- Exotic metal machining for titanium, Inconel, aluminum, and stainless steel

- Efficient material utilization to minimize waste and reduce costs

- Advanced metrology to ensure each part meets exact specifications

Our engineers have extensive expertise in solid modeling and product development, with Certified SolidWorks Professionals on staff. This allows us to assist customers in optimizing parts for manufacturability, reducing lead times, and improving overall efficiency. Trust Cutter Innovations to meet the quality of standards you expect.